Imagine a world where life-saving medications aren’t cooked up in vast chemical plants, but are instead brewed in humble fermentation tanks, much like your favorite craft beer. This isn’t science fiction; it’s the cutting-edge reality emerging from laboratories worldwide, where scientists are transforming ordinary beer yeast into microscopic drug factories for ‘smart drugs’.

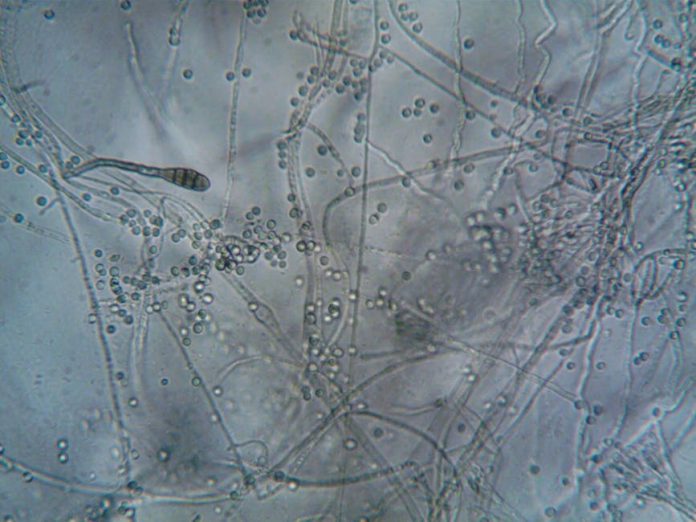

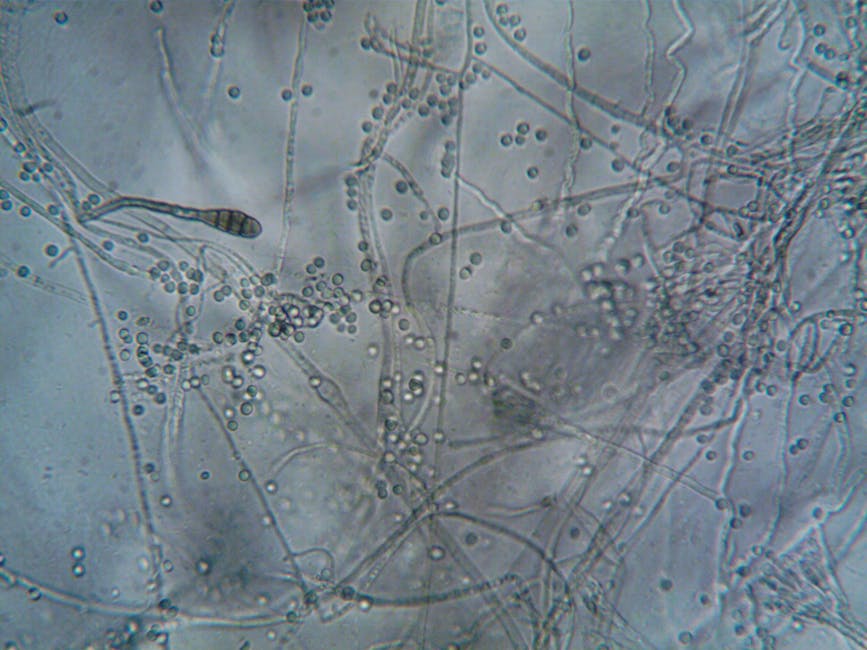

For centuries, Saccharomyces cerevisiae – the common beer yeast – has been our silent partner in baking bread and brewing alcoholic beverages. But its true potential is only now being unlocked by the power of synthetic biology. Researchers are genetically engineering this versatile microbe, reprogramming its natural metabolic pathways to synthesize complex pharmaceutical compounds that were previously difficult, expensive, or even impossible to produce.

So, what exactly are these ‘smart drugs’ and why is yeast the ideal candidate for their creation? ‘Smart drugs’ often refer to complex molecules, sometimes tailored for specific therapies, or those with highly precise mechanisms of action. Traditional chemical synthesis can be inefficient, generate toxic byproducts, or require rare plant sources. Yeast offers a cleaner, greener, and potentially much cheaper alternative.

By introducing new genes or tweaking existing ones, scientists can essentially turn yeast cells into living mini-bioreactors. These tiny factories can churn out a vast array of compounds, from precursor molecules for existing drugs to entirely new therapeutic agents. Think about complex painkillers that usually require vast poppy fields, or intricate anti-cancer compounds – all potentially produced with higher purity and at a fraction of the cost, without the ethical or supply chain complexities.

The benefits of this ‘yeast revolution’ are immense. Firstly, it promises a significant reduction in drug manufacturing costs, making essential medicines more accessible globally. Secondly, it offers unparalleled scalability; fermentation tanks can be rapidly expanded to meet demand. Thirdly, it’s a more sustainable approach, reducing reliance on resource-intensive agricultural practices or environmentally challenging chemical processes. Finally, it opens doors for rapid drug development and personalized medicine, where specific compounds could be brewed on-demand for individual patient needs.

While still in its early stages for many applications, the work on turning beer yeast into biopharmaceutical factories represents a paradigm shift in drug production. This unassuming microbe is poised to become a powerhouse in modern medicine, brewing a healthier, more accessible future, one ‘smart drug’ at a time.